In an age where architecture and engineering are rapidly evolving, the importance of precision in construction cannot be overstated. One of the key processes that contribute to this precision is steel detailing. This process serves as the bridge between design and execution, ensuring that every component of a structure is accurately conceptualized, created, and assembled. Today, we are diving deep into the steel detailing process to unravel its complexities and marvel at the craftsmanship that shapes our built environment.

What is Steel Detailing?

Steel detailing is the process of creating detailed drawings and specifications for the construction of structural steel. Essentially, these drawings serve as the blueprint for fabricators and contractors, outlining how to construct the steel elements of a building. The steel detailing process includes the preparation of Structural Steel Fabrication Drawings, which detail every piece of steel that will be used, including dimensions, connections, and material specifications.

Steel Fabrication Drawings represent the detailed breakdown of the steel elements from the structural drawings provided by the architects and engineers. They are crucial for ensuring the fabrication process goes smoothly and efficiently, as they guide the machinists and welders in creating the structural steel components.

What is Steel Detailing Services?

Steel Detailing Services are all about the nitty-gritty of turning architectural ideas into real-world steel structures. Think of them as the folks who take blueprints from architects and engineers and whip up the detailed plans that fabricators need to get the job done right. Here’s the lowdown:

- Detailed Drawings: These pros generate what are called Steel Detailing Drawings or Structural Steel Fabrication Drawings. They lay out every little detail—dimensions, materials, how everything fits together—so there’s no guesswork on site.

- Connection Specs: They get into the weeds with how different steel pieces connect—whether it’s welded, bolted, or riveted. It’s all about keeping that structure solid and standing strong.

- Fabrication Playbook: The drawings serve as the ultimate guide for fabricators, telling them how to cut, mold, and assemble steel parts without a hitch.

- Team Players: Steel detailers work closely with engineers and architects. They make sure the drawings align with the design vision and maintain the structural integrity everyone’s counting on.

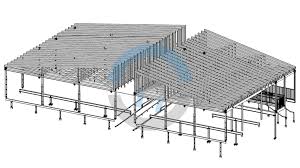

- 3D Wizardry: Nowadays, many detailers use high-tech stuff like Tekla to whip up 3D models of steel structures. This lets everyone visualize how it’ll all come together, spotting any potential hiccups before they happen.

- Quality Check: Accuracy is the name of the game. Steel Detailers are all about delivering top-notch drawings that help avoid screw-ups in fabrication and construction, keeping safety in check.

- As-Built Documentation: After everything’s built, they might also create as-built drawings to document how the finished structure turned out, noting any changes from the original plans.

The Steel Detailing Process: Step by Step

- Initial Review and Understanding of Designs: Before starting with any drawings, steel detailers review the architectural and structural plans. This initial step is crucial, as it allows them to understand the project’s overall scope. A comprehensive understanding of Architectural, Structural, and MEP (mechanical, electrical, and plumbing) drawings is essential to foresee any potential issues in the integration of the steel structure.

- Creation of Steel Structure Drawings: Once the detailers have a firm grasp of the designs, they enter the drafting phase. This involves creating Steel Structure Drawings, which outline every structural component. Detailers make use of sophisticated software like Tekla, enabling them to produce precise Steel Detailing Drawings aimed at preventing any construction-related mishaps.

- Incorporating Connection Details: In every steel structure, the connections between beams, columns, and other components are of utmost importance. These joints determine the stability and integrity of the entire framework. Detailing experts meticulously specify the type of connections (welded, bolted, or riveted) in their Structural Steel Detailing Services to ensure that the assembly of the steel structure is efficient and secure.

- Reviewing with Engineers and Architects: After creating the initial draft, detailers often seek feedback from the structural engineers and architects involved in the project. This collaborative effort is crucial, as it ensures that the drawings align with the structural integrity and performance requirements specified in the design.

- Finalizing Steel Fabrication Drawings: Once the input from the engineering and architectural teams has been integrated, the final Steel Fabrication Drawings are prepared. These drawings are extremely detailed and include dimensions, materials, and assembly instructions. They also encompass all necessary information that the fabricators will need to produce the steel components accurately.

- Production and Assembly: With the finalized drawings, the fabrication process begins. Workers at the fabrication facility use the Steel Detailing Drawings to cut, shape, and prepare the steel components. This phase often involves advanced machinery and techniques, ensuring every piece is manufactured to the specifications in the drawings.

- Quality Control: Quality control checks are critical during the production phase. Inspectors ensure that the fabricated components meet all outlined specifications and standards. This step is not just vital for compliance, but it also plays a key role in preventing any issues during the onsite assembly.

- Delivery and Erection: Once the components pass quality inspection, they are delivered to the construction site. The steel detailing process manifests itself anew during the erection phase, where the detailed drawings guide crews in assembling the steel structure according to the layout specified in the Steel Structure Drawings.

- Post-Construction Review: After the assembly is complete, a post-construction review ensures that everything conforms to the original design and standards. This phase may also involve creating as-built drawings, which document the completed structure, noting any deviations or changes that occurred during construction.

Why is Steel Detailing Important?

Steel detailing is an essential component of the construction industry. A well-executed detailing process leads to numerous benefits:

- Precision and Accuracy: The use of Steel Detailing Drawings minimizes errors during fabrication and construction, ensuring that components fit together seamlessly.

- Time Efficiency: By providing clear instructions and specifications, steel detailing streamlines the entire process from fabrication to erection, saving time and reducing potential rework.

- Cost-Effectiveness: Accurate detailing helps avoid costly mistakes and delays, as it minimizes the risk of needing adjustments or replacements once construction begins.

- Safety: Proper detailing enhances the safety of the structure by ensuring that all elements are accurately accounted for and securely connected.

- Collaboration: The process fosters communication between architects, engineers, and fabricators, creating a more cohesive workflow.

The Role of Technology in Steel Detailing

Modern steel detailing has significantly benefited from advancements in technology. Traditionally, detailers relied on manual drafting techniques, which were time-consuming and prone to errors. Today, software programs such as Tekla have revolutionized the detailing process. Tekla Steel Detailing Services provide powerful tools for 3D modeling, allowing detailers to visualize the entire project before construction begins.

These technologies not only enhance accuracy but also improve collaboration among all parties involved. Stakeholders can share, collaborate, and make necessary adjustments in real-time, creating a more efficient process overall.

Choosing the Right Steel Detailing Company

With so many players in the market, selecting the right steel detailing company can be overwhelming. Here are a few criteria to consider:

- Experience and Expertise: Look for a company that specializes in Structural Steel Detailing and has a proven track record of successful projects.

- Technology Utilization: Ensure they utilize the latest software and technology, such as Tekla, to guarantee precision and efficiency in their detailing services.

- Customer Reviews: Seek out reviews and testimonials from previous clients to gauge the quality of their work and customer service.

- Commitment to Quality: The best steel detailing companies prioritize quality control and adhere to industry standards.

The world of construction and architecture is endless, with innovation and creativity consistently pushing boundaries. At the heart of this evolution lies the steel detailing process, a meticulous journey that transforms artistic visions into functional realities. By understanding and appreciating the complete steel detailing process, we can recognize the dedication and craftsmanship that contribute to the enduring structures around us.

As stakeholders in the construction industry, whether you are architects, engineers, or clients, understanding steel detailing empowers you to make informed decisions that contribute to the success of your projects. The next time you admire a magnificent steel structure, take a moment to appreciate the intricate details and precision that went into its creation through the art of steel detailing.

Steel Roof Detailing Services

Check silicon Valley's latest blog on the Steel Roof Detailing Services

Discover more

Understanding the complete Steel Detailing Services Process